Where Excellence in Solar Power Is Built

Our Factory is located in Telefunken Technology Park in Heilbronn, Germany. AZUR SPACE occupies several buildings with multiple floors each on campus.

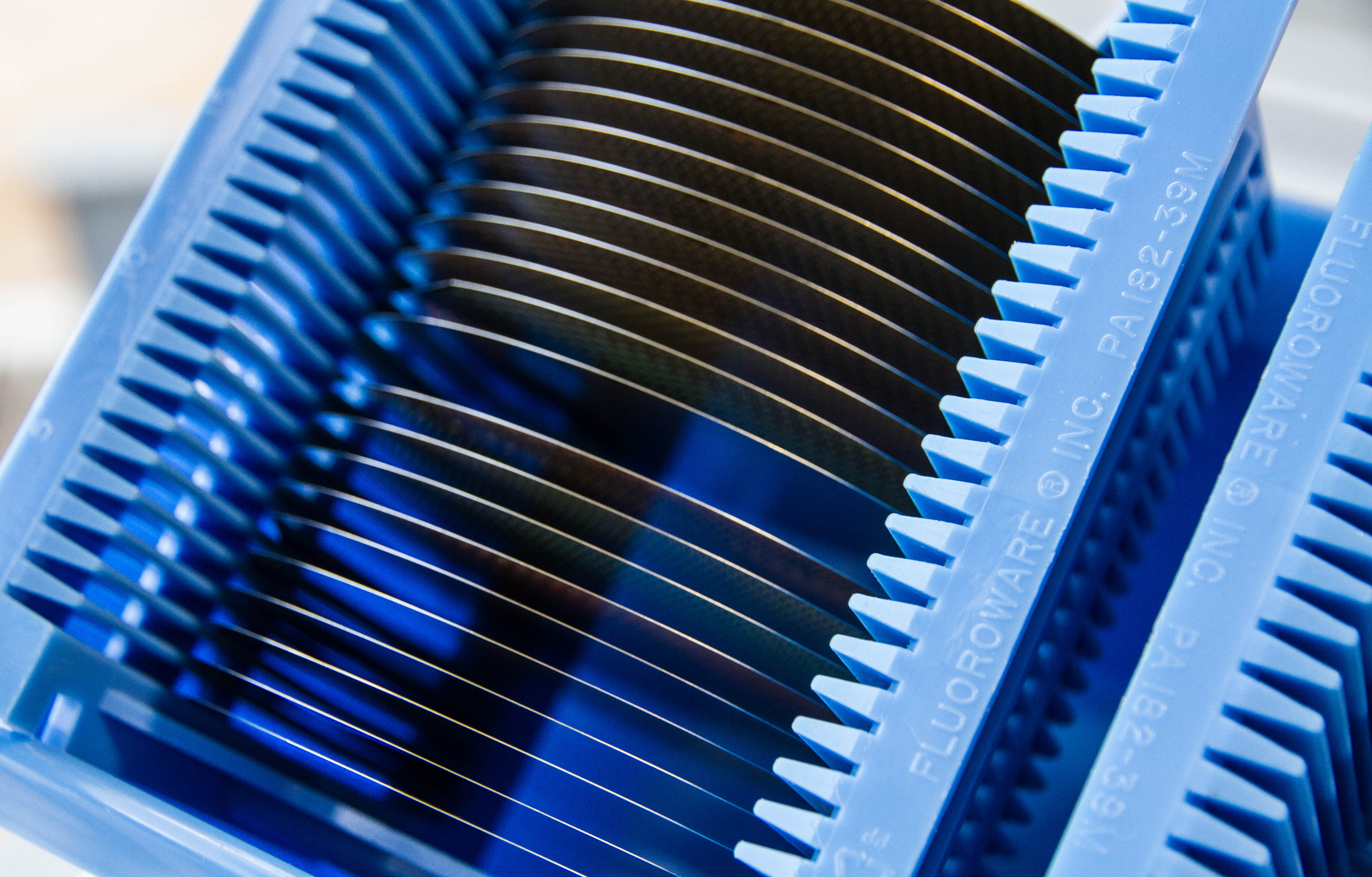

Precision Begins at the Wafer

Our products begin with Germanium wafer blanks, in multiple wafer sizes, produced to our proprietary specification. Wafers originate from multiple qualified suppliers from around the world, including 5N Plus’ facility in St. George, Utah, U.S.A.

High-Tech Cleanroom Fabrication

For fabrication of solar cell structures, we use a sophisticated metal-organic vapor phase epitaxy (MOVPE) process, which has been continuously developed since 1999 when epi tools were first installed at AZUR SPACE.

The maximum performance of a multi-junction device is only achievable if the composition, thickness and doping level of each of its many semiconductor layers are precisely adjusted inside our MOCVD tools.

The maximum performance of a multi-junction device is only achievable if the composition, thickness and doping level of each of its many semiconductor layers are precisely adjusted inside our MOCVD tools.

This exclusive process based on AZUR SPACE´s own know-how is now applied for cost effective deposition of high efficiency solar cell structures on 100 mm and 150 mm substrates..

The resulting epitaxial layer stack comprises upwards of 70 distinctly grown layers totaling just a few microns in thickness, but building the foundation of generating highest solar power conversions in the industry.

Wafer and Cell Manufacturing facilities of AZUR SPACE located across multiple floors in our strictly controlled, modern clean rooms, encompass thousands of square meters.

Wafer and Cell Manufacturing facilities of AZUR SPACE located across multiple floors in our strictly controlled, modern clean rooms, encompass thousands of square meters.

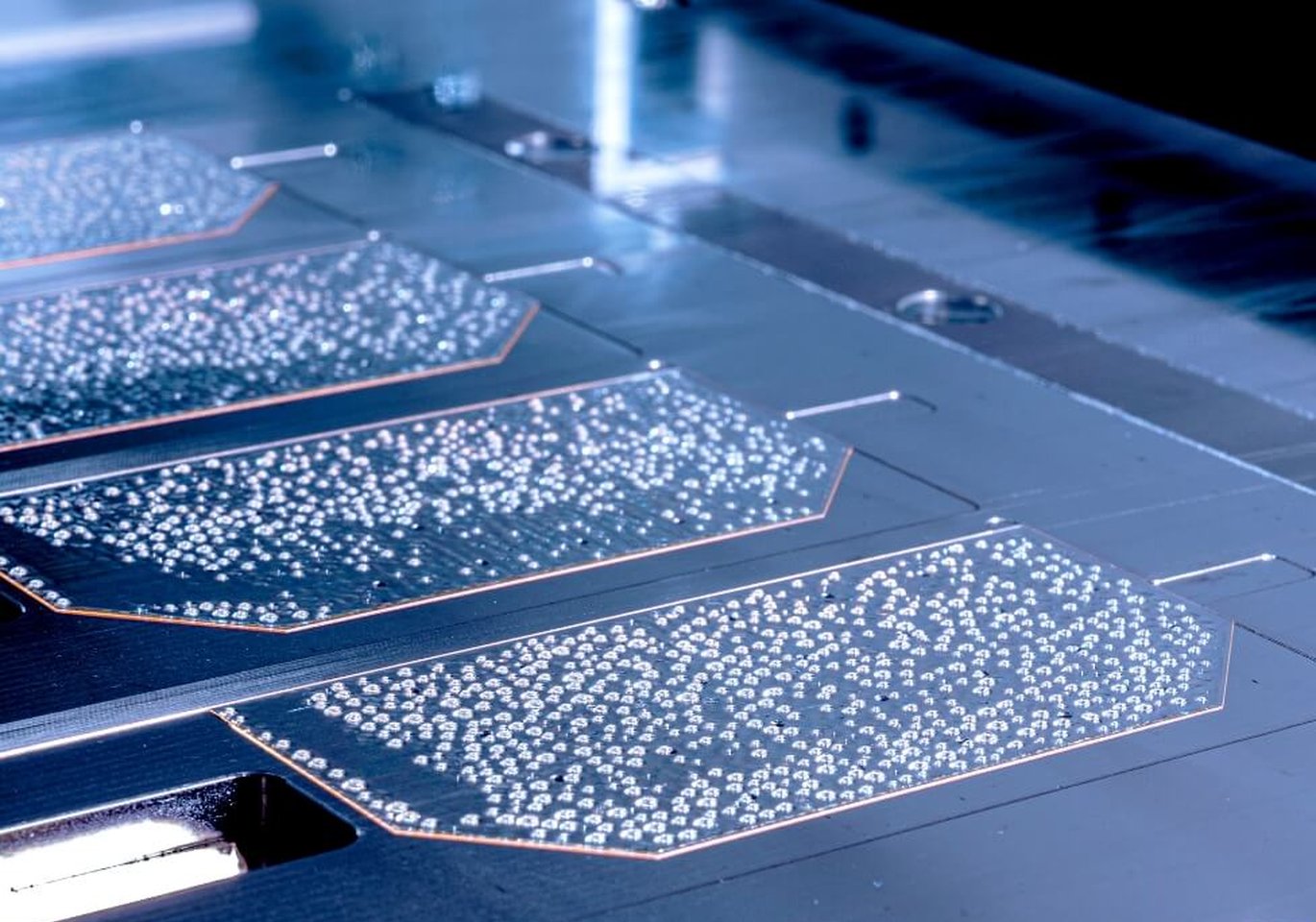

Due to the specific structure and design of multi-junctions solar cells, our photolithography-based technology processes are more similar to the ones of the optoelectronic industry than those of conventional photovoltaics.

Their features such as optimal utilization of the valuable semiconductor material, very fine (up to few microns) front contact grid lines for minimal shadowing, specific contact alloys for reducing resistive losses and highly efficient broadband antireflective coatings enable best cell performance at a competitive price.

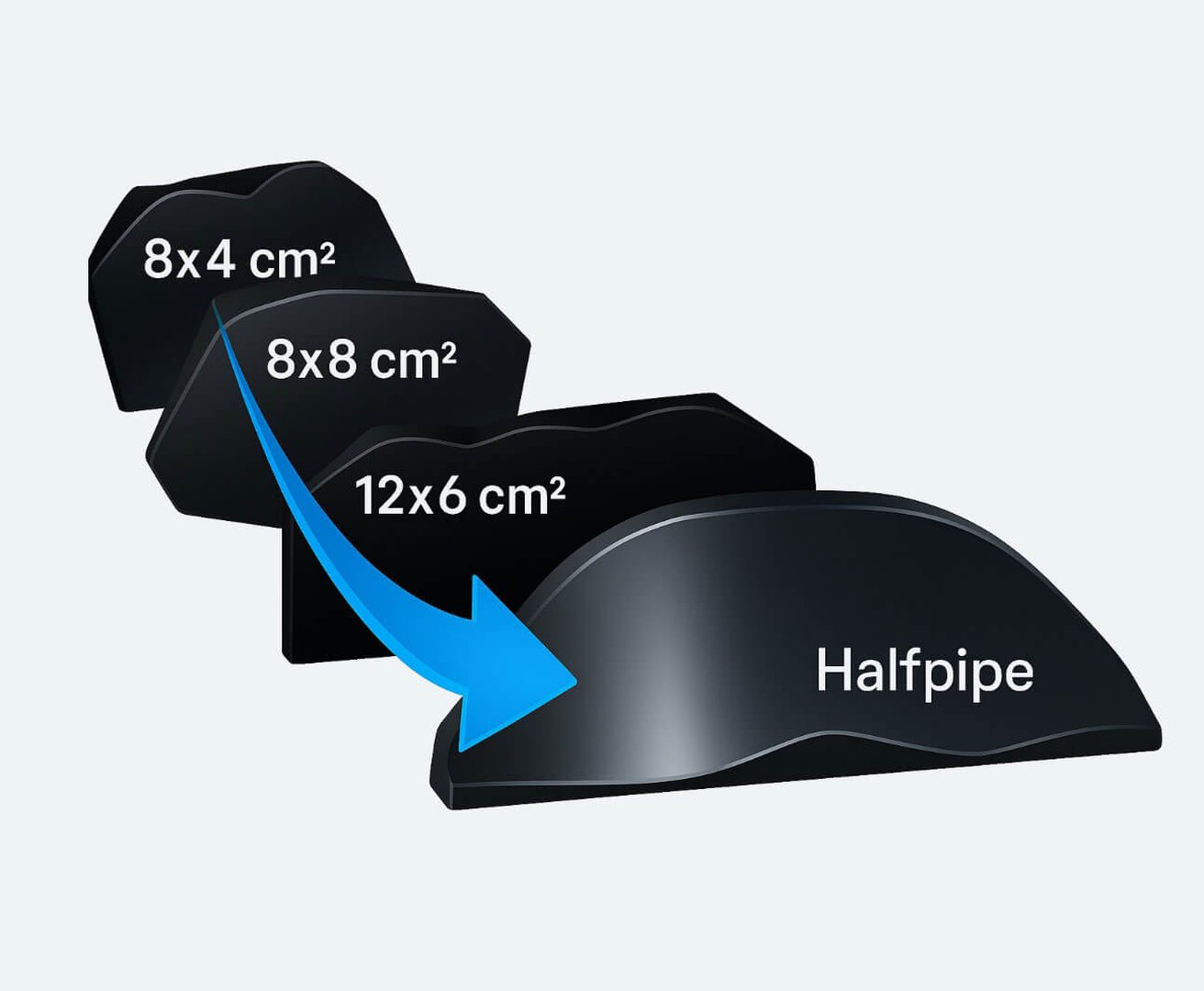

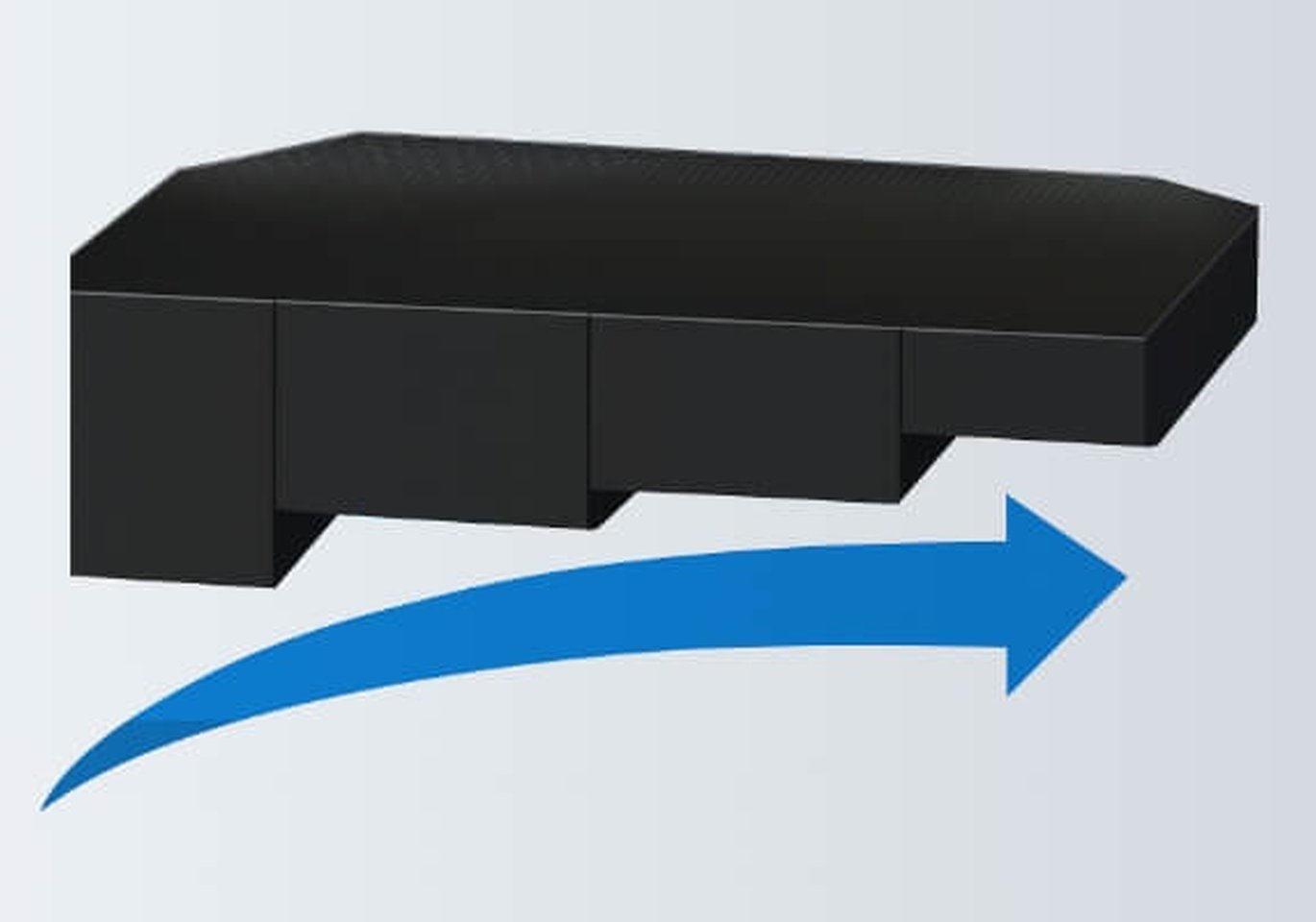

Flexible Cell Sizing, Standard Technology

Our cell sizes range from just a few square centimeters up to more than 82 cm2, depending on program requirements. Of course, AZUR SPACE encourages the use of standard cell geometries as the most efficient and cost-effective solution whenever possible.

Controlled Processes, Proven Results

Well trained and experienced personnel oversee each step of the fabrication process.

Careful technical scrutiny and oversight

Thickness options to enable mass reduction

Final Integration and Protection

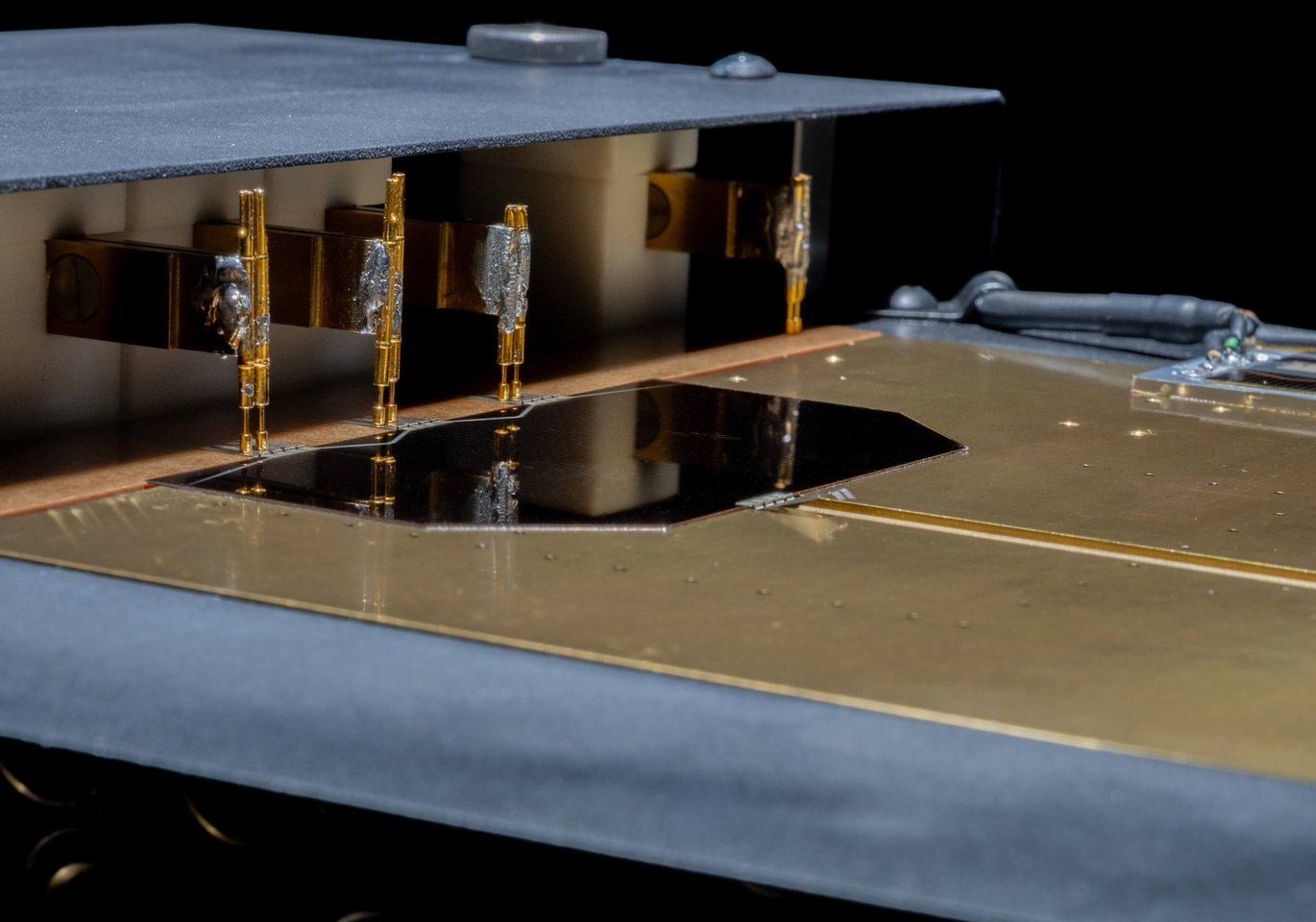

Once the cells are completed, they move to the Assembly area to be combined with diode, interconnects and coverglass to form a Solar Cell Assembly. Discrete diodes provide electrical protection in the event of shadowing in space, causing reverse current flow. Welded interconnectors enable the connection in series of multiple devices to form strings, or circuits.

Optical space grade coverglasses are procured from multiple vendors worldwide and enable enhanced environmental protection on orbit. All assembly devices are subjected to multiple size, weight, dimensional, electrical and visual screenings to ensure a quality result.

Tested to Meet the Highest Standards

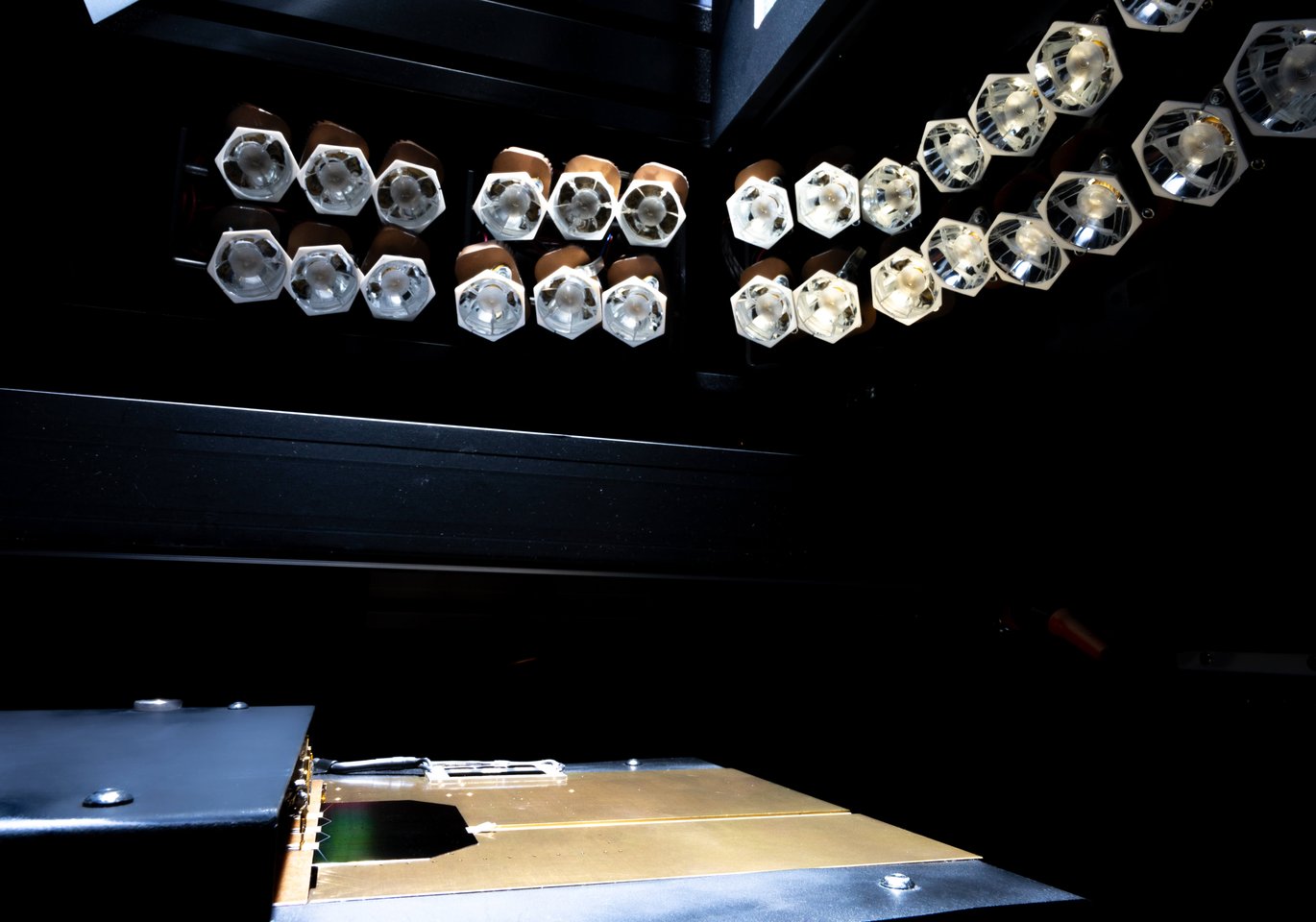

We use AAA sun simulators meticulously calibrated with own isotype standard solar cells derived from our products and characterized under AM0 spectrum by balloon flights and synthetic calibration.

We furthermore monitor our products' EOL performance by regular characterization of our cells after electron irradiation.

And most importantly, all our products need to pass several acceptance tests to ensure 100% compliance to specification.

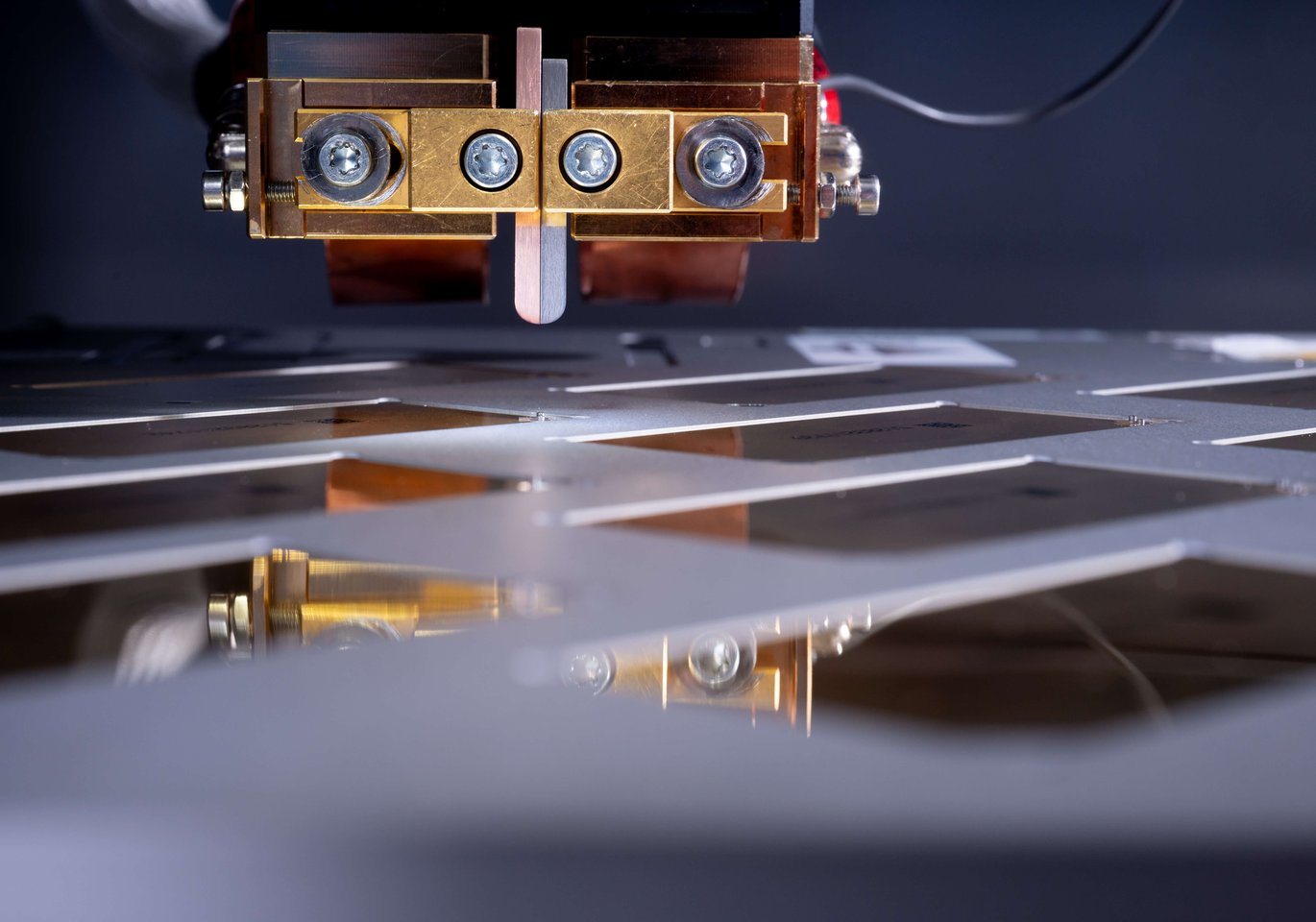

Performance tests with automated cell contact and characterization

Sun simulators calibrated to the individual products to ensure reliable measurements